Building another TM500 / TM5000 Mainframe Test Unit

Several years ago I made a very

simple test plug for TM mainframes. Basically the only thing it did was

route the various voltages and transistor pins available on the interface

to the front panel. So inspired by discussions on the Tekscopes forum and seen

what other have done I decided to make another unit, a little more sophistcated

than my old.

These are the functions I wanted:

1: Test that the two 25V AC windings are OK, i.e. there is no short to

ground and that the phase between them is correct.

2: Show DC voltages on a digital display.

3: Show AC voltages on a digital display.

4: Momentary load the

selected DC voltage with about 0.5A and show DC voltage and AC ripple at the same time.

5: Output the selected voltage to the front panel for a more accurate reading on

an external DVM.

6: Output the transistor pins to the front panel to be

viewed on a Curve Tracer.

Many areas on the pictures below can be clicked to show a close up.

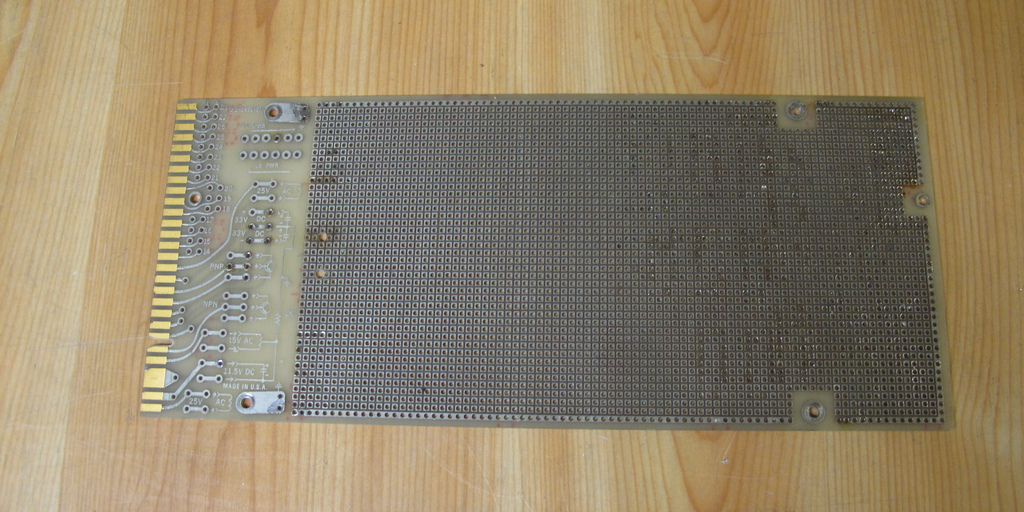

The donor plug this time was this one. I had no idea what it is for and it contained no active parts so only the mechanical part could be used.

Since the donor didn't have an

interface connector and I needed access to all voltages and the transistors I

used an original board from a blank plug kit.

The new plug had to have boards

on both sides of the board so I could only use the interface connector since the

original board is not at the center of the plug.

I sawed it

off a bit to the right of the mounting holes in the first vertical column of

holes and then, as before, made an aluminum subframe with enough offset

to

accomodate boards on both sides.

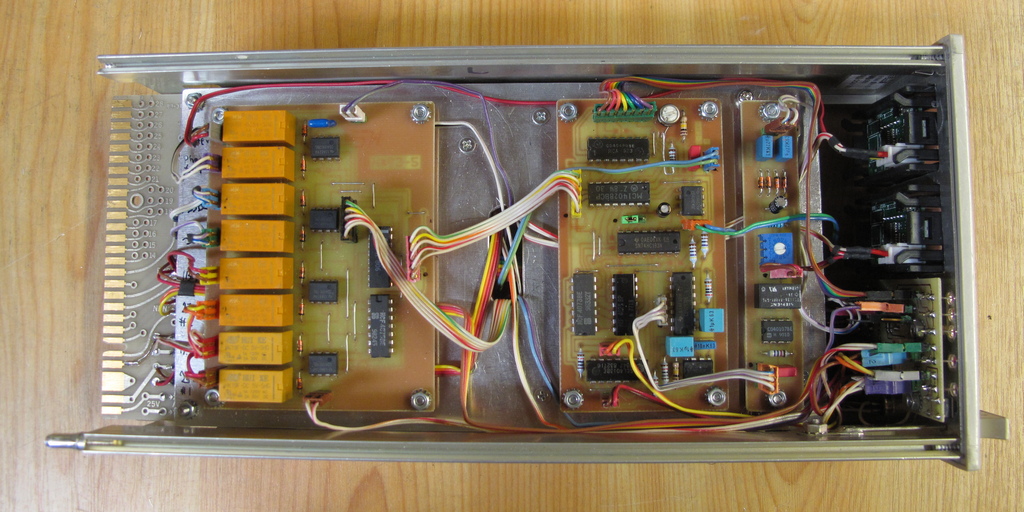

The

right inside: Float/Phase board, Load board and Power supply board. The

power to meters and all boards originates from the 17.5VAC winding and the

rectified 5V is grounded in the

chassi. Since the digital meters can only show positive voltages the negative

voltage had to reversed so the power to the meters

had to be floating therefore I

used a TRACO DC-DC converter with floating output. The 17.VAC winding is center

tapped to ground via a 1k resistor in TM500

mainframes but in TM5000

mainframes it is hardwired directly to ground which I found out the hard way.

Therefore the second TRACO DC-DC converter instead

of a simple 7805. The batteries are for the Float

test of the 25VAC windings which is done with power off. This test is off

course is disabled when power is on.

The

left side: Relay board, Control board and AC-to-DC board. I didn't use

the original pull tab and latch since I see no reason to have those in a plugin

that will

be moved in and out all the time. Instead I

used a pull tab from a 7k plugin with a modified release bar screwed directly to

the frame.

Aug 2024 change: The AC-to-DC

board was redesigned to Schottky diodes for the rectifier instead of common

1N4148 diodes.

Also all components except for the variable resistor, relay

and IC are now SMD on the bottom side of the board.

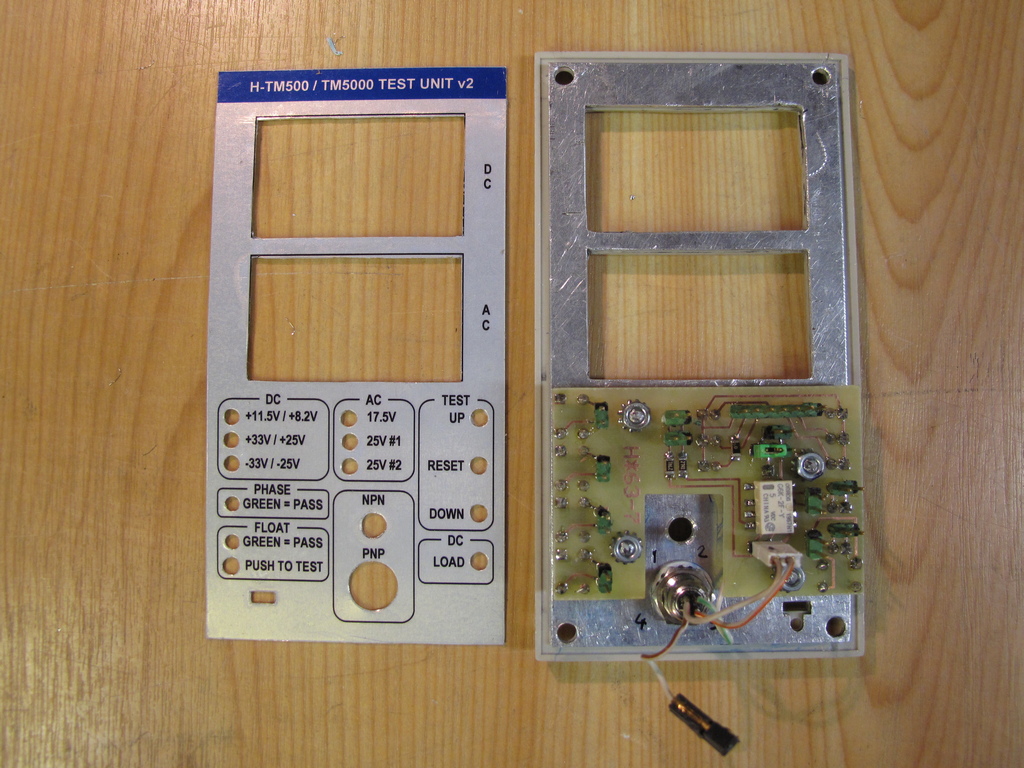

Front

Panel and Front Panel board The round connector on center bottom is

a 4 pole LEMO connector which outputs the transistor pins or the currently

displayed voltage to the CT

interface pod. The green jumper just above the small relay selects either

transistor pins to the output all the time or only when

power is off and the measurements

when power is on.

The CT

interface pod: It uses a USB connector and a modified USB cable to

connect to the front panel. While power is on and measurements are enabled on

the

front panel board the selected

measurement is available on the the BNC connectors for a differential scope or

DMM cables. The measurements could be routed

to the C and B connectors so the

pod could be connected directly to the DMM by pressing the switch in the hole.

In that case E is disconnected from GND and

the condition will remain until

it is powered off. If measurements are not enabled on the front panel board or

the power is off the mainframe's transistor pins are

available on the E, B and C

connectors.

The finished unit testing a TM501. Click on it for a short video.

Schematics, parts List and layouts of all boards here.

TM500 Mainfrmae Test unit TM5000 Mainframe Test unit TM500 Mainfrmae Tester TM5000 Mainframe Tester

Email me with comments. /Håkan

Home / Go back